Table of Contents

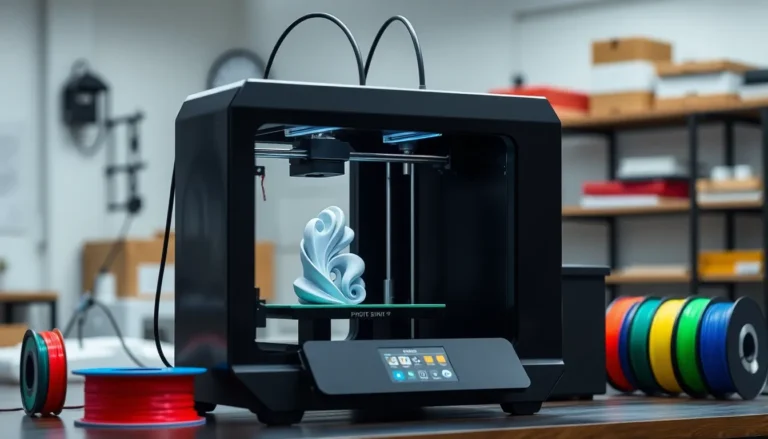

ToggleImagine a world where building homes is as easy as hitting “print” on your 3D printer. Welcome to the fascinating realm of 3D concrete printing, where creativity meets cutting-edge technology. This innovative process is revolutionizing construction, making it faster, more efficient, and surprisingly eco-friendly.

Overview Of 3D Concrete Printing

3D concrete printing refers to an innovative construction method that utilizes technology to create structures layer by layer using concrete materials. This technique enhances efficiency in building processes, significantly reducing both time and labor costs. Projects that once took months can now see completion within weeks, demonstrating remarkable speed.

Utilization of 3D concrete printing simplifies complex designs and allows for greater creativity in architecture. Builders can produce intricate shapes and customized features that traditional methods struggle to achieve. The ability to design and modify projects dynamically during construction improves flexibility and reduces waste of materials.

Environmental benefits accompany 3D concrete printing as well. This method consumes less energy and generates less waste compared to conventional building practices. It promotes sustainability by allowing for the use of recycled materials in the concrete mix, thus minimizing the carbon footprint associated with construction.

Several companies and research institutions are advancing 3D concrete printing technology, developing new materials and methods to enhance overall performance. These innovations will likely lead to more widespread adoption in the industry. As the construction sector continues to embrace digitization, 3D concrete printing stands out as a transformative force.

Advantages Of 3D Concrete Printing

3D concrete printing offers numerous advantages that can enhance construction practices significantly.

Speed And Efficiency

Projects benefit from drastic reductions in construction time. Builders can complete structures in weeks instead of months, streamlining the entire process. Layer-by-layer construction enables real-time adjustments, promoting efficiency. Advanced technology minimizes delays associated with traditional building methods. Automation plays a vital role, allowing teams to focus on other critical tasks.

Cost-Effectiveness

This innovative approach lowers both material and labor costs. Fewer workers are required due to reduced manual labor, leading to significant savings. Additionally, less waste material results in lower disposal costs. Use of precise amounts of concrete avoids overages and minimizes excess expenses. Organizations effectively manage budgets with accurate project timelines and lower financial risks.

Design Flexibility

Architects and builders enjoy unparalleled freedom in design. 3D printing allows for complex shapes that traditional techniques struggle to create. Customization capabilities enable tailored features to suit specific needs. Unique, aesthetically pleasing structures become feasible. This flexibility inspires creativity, transforming standard building practices into extraordinary, innovative results.

Applications Of 3D Concrete Printing

3D concrete printing serves diverse applications across various sectors, showcasing its versatility and impact on modern construction methods.

Residential Construction

Residential construction benefits significantly from this technology. Builders can create entire homes in a matter of weeks, drastically reducing the time needed compared to conventional techniques. Customized designs become feasible, allowing homeowners to personalize their living spaces with unique shapes and features. The integration of smart technologies results in homes that not only look appealing but also enhance energy efficiency. This approach minimizes waste, as material is used precisely, aligning with sustainable building practices.

Infrastructure Projects

Infrastructure projects increasingly adopt 3D concrete printing for its efficiency and cost-effectiveness. Roadways, bridges, and tunnels can be constructed more rapidly, with fewer labor requirements. Utilities find it easier to manage logistics due to the streamlined processes involved. Structural integrity remains uncompromised, providing robust and resilient infrastructure. Rapid prototyping allows engineers to test different models before full-scale production, ensuring optimal performance. As cities expand, this method supports the need for quicker and sustainable infrastructure solutions.

Artistic Installations

Artistic installations benefit from the creative flexibility offered by 3D printing. Artists and designers explore complex forms that traditional methods struggle to achieve, resulting in eye-catching sculptures and structures. Customized features enhance visual appeal, making installations unique and engaging. Collaboration between artists and architects fosters innovation, pushing the boundaries of art in public spaces. This technology simplifies the creation of intricate designs, encouraging more artists to incorporate concrete in their work, leading to a fresh wave of artistic expression.

Challenges And Limitations

3D concrete printing faces several challenges that need addressing for broader adoption. Material limitations and regulatory hurdles create obstacles in maximizing its potential.

Material Limitations

Material performance remains a key issue in 3D concrete printing. Traditional concrete types may not offer the required strength or flexibility needed for innovative designs. Alternative materials, including bio-based composites, are in development, yet they may not fully match the properties of conventional concrete. Additionally, curing times can vary, influencing the construction speed. The reliance on specific mixes can also lead to inconsistencies in quality and performance. Research is ongoing to develop advanced materials that enhance structural integrity while lowering environmental impact.

Regulatory Hurdles

Regulatory hurdles hinder the integration of 3D concrete printing in mainstream construction. Many existing building codes do not accommodate the unique aspects of 3D printing technology. Inspectors often lack expertise in assessing 3D-printed structures, leading to delays in project approvals. Local authorities may impose stringent regulations that affect material use and construction processes. Innovations in this sector depend on collaboration with regulators to establish guidelines that promote safety without stifling creativity. Overall, navigating these challenges requires active engagement from stakeholders and government bodies.

Future Trends In 3D Concrete Printing

Emerging trends indicate a significant shift in the landscape of 3D concrete printing. Innovations in technology continue to enhance its capabilities and applications across sectors.

Technological Innovations

Breakthroughs in material science contribute significantly to advancements in 3D concrete printing. Researchers are exploring new concrete mixtures designed for improved strength and flexibility. Enhanced printer designs enable faster layer deposition, which accelerates the construction process. Robotics integration further streamlines operations, allowing for precise, automated construction methods. Smart sensors provide real-time feedback during printing, ensuring consistency and quality. These technological developments solidify 3D printing’s place in the construction sector, increasing both efficiency and creativity.

Market Growth Predictions

Research forecasts a rapid expansion in the 3D concrete printing market over the next decade. Analysts project a compound annual growth rate (CAGR) of around 25%, fueled by demand for construction efficiency and sustainability. Businesses are increasingly recognizing the benefits of reduced labor costs and improved design flexibility. As more companies adopt this technology, the market’s value could exceed $1.5 billion by 2030. Rising interest from investors also supports growth, as innovations promise diverse applications beyond construction. This upward trajectory positions 3D concrete printing as a critical player in the future of the construction industry.

3D concrete printing stands at the forefront of the construction revolution. It’s reshaping how structures are designed and built, offering speed and efficiency that traditional methods can’t match. As technology advances and new materials emerge, the potential applications for this innovative approach will only expand.

While challenges remain in regulation and material performance, the ongoing commitment from industry leaders and researchers promises to overcome these hurdles. The future of construction is bright with 3D concrete printing, paving the way for sustainable practices and creative architectural solutions. Embracing this technology could lead to a more efficient and environmentally friendly building landscape.