Table of Contents

ToggleIn the world of 3D printing, layer height is the unsung hero that can make or break a project. Imagine crafting a masterpiece only to discover it resembles a lumpy potato instead of the sleek design you envisioned. Choosing the right layer height isn’t just a technical decision; it’s like picking the perfect outfit for a first date—too much or too little can lead to disastrous results.

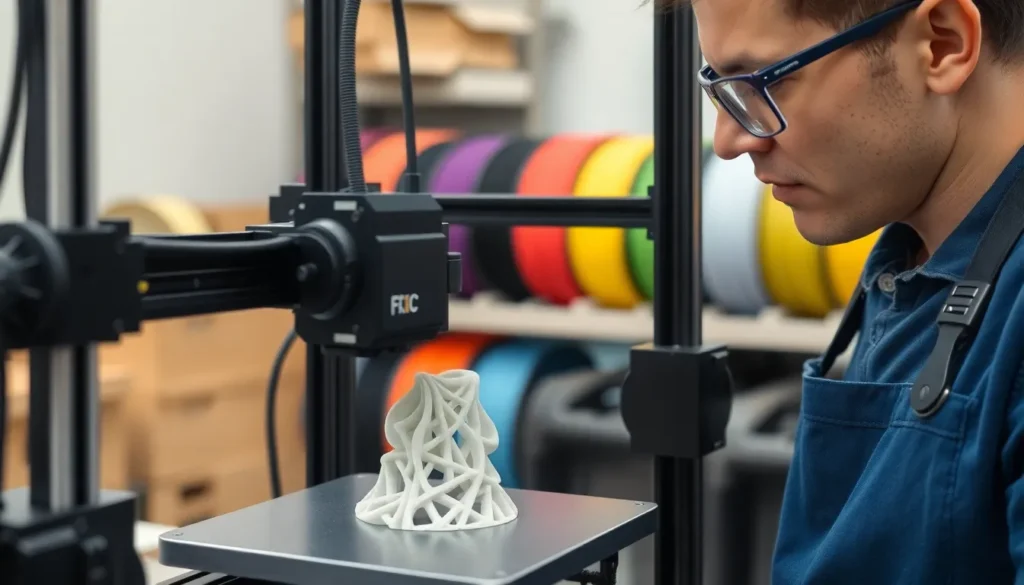

Overview of Layer Height 3D Printing

Layer height significantly influences the overall quality of 3D printed models. Measured in millimeters, it defines the thickness of each individual layer applied during the printing process. Standard layer heights range from 0.1 mm to 0.3 mm, though choices may vary based on specific project needs.

Choosing a smaller layer height, like 0.1 mm, enhances detail and precision. This option results in smoother surfaces and more intricate designs. However, it also increases the printing time, as more layers are required to complete a model. Thus, a balance between resolution and speed becomes crucial.

Conversely, a larger layer height, such as 0.3 mm, reduces print time but can sacrifice detail. Layer heights of 0.3 mm are beneficial for larger, less detailed objects, where rapid production takes precedence over fine details.

Material choice also impacts optimal layer height. Different filaments may respond better to specific heights, affecting adhesion and overall print quality. For example, PLA often performs well with various layer heights, while flexible materials may require larger settings to prevent issues.

Additionally, layer height interacts with print speed. Increasing the print speed alongside a larger layer height can lead to warping or poor layer adhesion. Maintaining a controlled print environment minimizes these risks, ensuring consistent results.

Individuals seeking high-quality prints must carefully consider layer height in conjunction with other parameters. They need to experiment with different heights to identify the best match for their specific applications.

Importance of Layer Height

Layer height significantly influences the final outcome of 3D printed objects. Choices made regarding this parameter directly affect both print quality and speed.

Impact on Print Quality

Print quality varies with layer height. Smaller heights, typically around 0.1 mm, provide enhanced detail and smoothness. Intricate designs benefit from these finer settings, achieving high levels of precision. Larger heights, such as 0.3 mm, tend to produce less detail but focus on a faster broader print. Surface finish may also suffer with larger heights, leading to visible layer lines that can detract from aesthetics. Additionally, certain materials perform optimally at specific layer heights, ensuring dependable adhesion and overall quality. Observing these nuances plays a vital role in mastering successful 3D printing.

Effect on Printing Speed

Printing speed depends heavily on selected layer height. Larger heights reduce printing time by requiring fewer layers to build an object. A height of 0.3 mm, for example, allows for quicker projects, making it advantageous when time constraints are present. However, increasing the speed without careful consideration of layer height can lead to complications like warping and poor adhesion. Smaller layer heights, while yielding higher quality, extend print durations significantly due to the increased number of layers. Striking a balance between quality and speed is essential for achieving desired results in 3D printing projects.

Choosing the Right Layer Height

Selecting the right layer height enhances the overall print quality and efficiency. Factors such as the intended application and material type impact this decision significantly.

Standard Heights for Different Applications

Standard layer heights typically range from 0.1 mm to 0.3 mm. For detailed models like miniatures and intricate designs, a height of 0.1 mm is ideal, providing exceptional surface quality and precision. In contrast, a height of 0.3 mm suits larger prints such as prototypes or functional parts, where speed takes precedence over detail. Additionally, designers may choose intermediate heights to balance detail and print time, often opting for 0.2 mm for versatile applications. Each choice affects the final outcome, making awareness of these standards essential for successful 3D printing.

Factors Influencing Layer Height Selection

Several factors influence the selection of layer height. First, the print material significantly shapes performance, with certain filaments responding better to specific heights. Temperature stability and adhesion properties must also be considered, as some materials like PLA function well across various settings. Furthermore, the printer’s capabilities and resolution affect achievable quality. Users should assess both print speed and desired detail to strike a balance. Ultimately, experimentation plays a crucial role in determining the most effective layer height for individual projects while achieving optimal results in print quality and efficiency.

Advanced Techniques in Layer Height 3D Printing

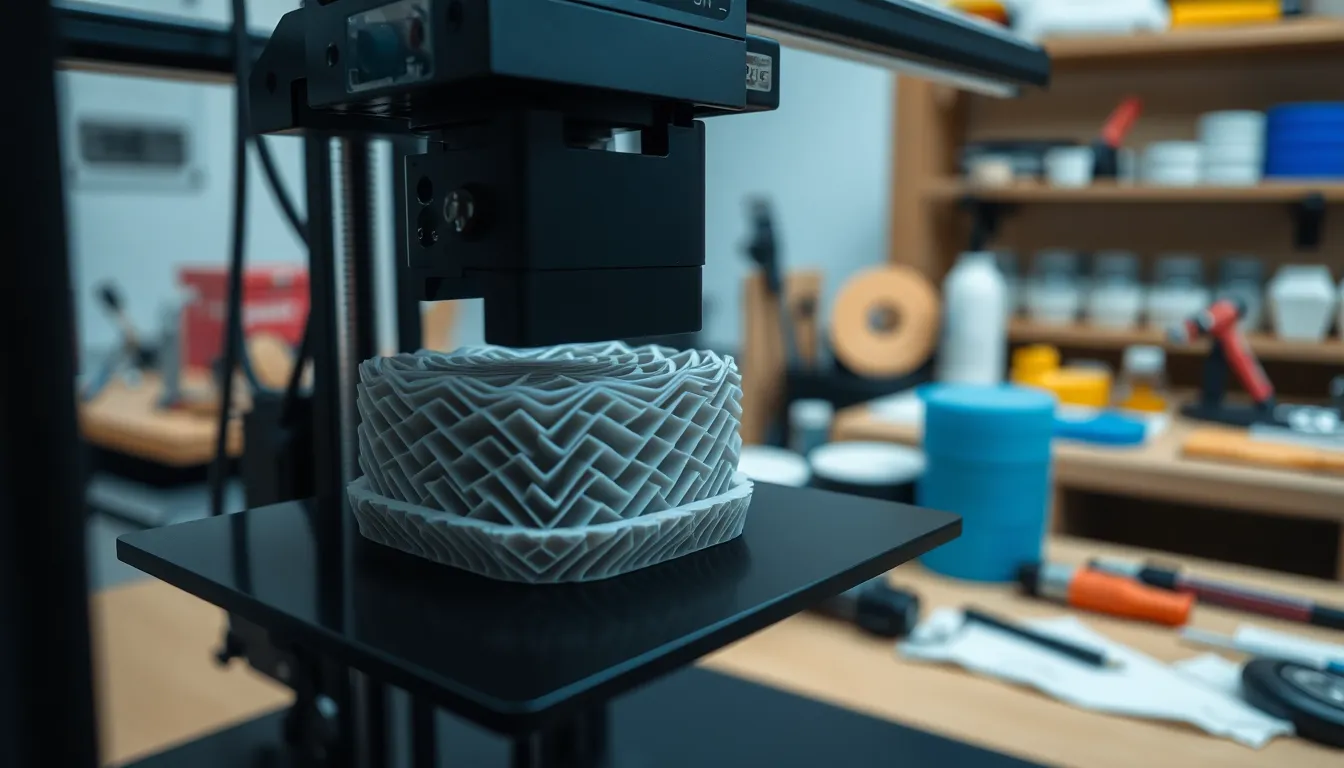

Optimizing layer height can significantly enhance 3D printing outcomes. Advanced techniques, such as variable layer height printing, offer unique benefits.

Variable Layer Height Printing

Variable layer height printing allows designers to adjust layer thickness throughout the print. It supports detailed areas with smaller layer heights while using larger heights for less intricate sections. This flexibility balances detail and print efficiency. For instance, a model may require fine details in specific regions and broader layers in others. By using this approach, one can increase print speed without compromising overall quality. Successful variable height printing relies on the slicer’s ability to manage transitions smoothly. Overall, this technique fosters customization for diverse projects.

Post-Processing Techniques

Post-processing techniques improve the final aesthetic and functional quality of prints. Common methods include sanding, painting, and applying coatings. Sanding eliminates visible layer lines and enhances surface texture. Painting can add colors and finishes to models, providing a polished appearance. Coatings, such as epoxy resin, offer added durability and protection. Effective post-processing enhances both the look and longevity of prints, making them more appealing for end-users. Experimenting with various techniques allows individuals to find the best methods for specific materials and projects. Overall, these techniques elevate 3D printed items, ensuring they meet professional standards.

Layer height is a pivotal factor in achieving quality in 3D printing. It directly influences the detail and finish of printed objects. By understanding the nuances of different layer heights, designers can make informed choices that align with their project goals.

Whether opting for finer details or faster prints, the right layer height can significantly impact the overall outcome. Experimentation and careful consideration of materials and techniques will lead to optimal results. As 3D printing continues to evolve, mastering layer height remains essential for anyone aiming to produce high-quality prints that meet both aesthetic and functional standards.