Table of Contents

ToggleIn today’s fast-paced digital landscape, 3D production techniques have revolutionized the way creators bring their visions to life. From stunning animations to intricate models, these techniques offer endless possibilities for artists, designers, and filmmakers alike. As technology continues to evolve, understanding these methods becomes essential for anyone looking to stay ahead in the creative industry.

Whether it’s through 3D printing, computer-generated imagery, or virtual reality, the impact of 3D production is undeniable. These tools not only enhance visual storytelling but also streamline workflows, making it easier to translate ideas into tangible realities. As the demand for immersive experiences grows, exploring the latest advancements in 3D production techniques is more important than ever.

Overview of 3D Production Techniques

3D production techniques encompass a range of methods that enable the creation of three-dimensional objects and environments. Key techniques include:

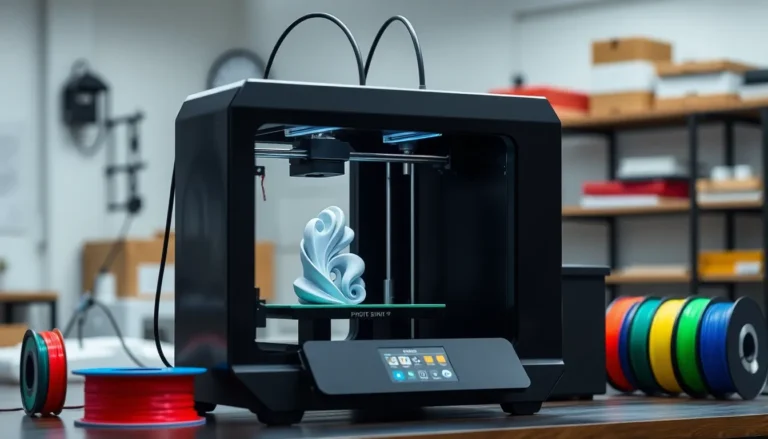

- 3D Printing: 3D printing, also known as additive manufacturing, fabricates physical objects layer by layer from digital models. This technique allows for rapid prototyping and customization, making it popular among engineers, designers, and artists.

- Computer-Generated Imagery (CGI): CGI involves creating still or animated visual content using computer software. It’s widely used in film, television, and video games, enhancing storytelling by providing realistic visuals and engaging special effects.

- Virtual Reality (VR): VR immerses users in simulated environments through headsets and interactive systems. This technique enhances user experience in gaming, training, and education, allowing for experiential learning and exploration.

- 3D Animation: 3D animation manipulates digital models to create the illusion of movement. This technique finds applications in film, advertising, and online content, enabling creators to produce captivating stories and visuals.

- Motion Capture: Motion capture records the movement of real objects or people and translates it into digital models. This technique is extensively used in film production and video games to create lifelike characters and realistic actions.

Each of these techniques plays a vital role in various fields, including entertainment, education, and industrial design, driving innovation and creativity in 3D production.

Types of 3D Production Techniques

3D production techniques can be categorized into several distinct methods, each offering unique advantages for various applications. Understanding these types helps professionals select the best approach for their projects.

Additive Manufacturing

Additive manufacturing, commonly known as 3D printing, builds objects layer by layer. This method utilizes materials like plastics, metals, and ceramics to create complex geometries. Industries such as aerospace, automotive, and healthcare benefit from this technique for rapid prototyping and customized solutions. For example, aerospace manufacturers produce lightweight components to improve fuel efficiency. Moreover, medical professionals use additive manufacturing to create patient-specific implants and prosthetics.

Subtractive Manufacturing

Subtractive manufacturing involves removing material from a solid block to create a desired shape. Techniques such as CNC (Computer Numerical Control) machining and laser cutting are standard in this field. These methods yield high precision and are suitable for producing detailed parts. Industries like manufacturing and automotive utilize subtractive techniques for producing intricate components. For instance, CNC machining allows for the creation of complex engine parts with tight tolerances.

Hybrid Techniques

Hybrid techniques combine additive and subtractive manufacturing to leverage the strengths of both methods. This approach enables the production of intricate features while ensuring precise finishing. Industries often employ hybrid techniques to optimize production processes and material usage. For example, a manufacturer might create a part using additive methods and then use CNC machining for surface finishing, combining efficiency and precision in a single workflow. Hybrid techniques provide versatility that caters to complex engineering demands.

Applications of 3D Production Techniques

3D production techniques find extensive applications across many industries, enhancing creativity and efficiency. By leveraging these methods, professionals create innovative solutions in varied fields.

Industries Utilizing 3D Techniques

- Entertainment: Filmmakers and game developers use CGI and 3D animation to craft realistic visuals and captivating experiences. Major franchises rely on these techniques for visual effects.

- Healthcare: 3D printing assists in creating custom prosthetics and anatomical models. Surgeons utilize printed models for pre-operative planning, improving patient outcomes.

- Aerospace: Engineers employ additive manufacturing for producing lightweight parts. This reduces material waste and streamlines production timelines, enhancing safety and efficiency.

- Architecture: Architects use 3D modeling software to visualize designs in realistic formats. Virtual simulations help clients understand projects before construction begins.

- Education: Educational institutions incorporate VR to provide immersive learning experiences. Students engage in interactive simulations that enhance understanding of complex concepts.

Benefits of 3D Production in Various Fields

- Customization: 3D production techniques enable tailored solutions for individual needs, particularly in healthcare and consumer products. Custom items enhance user satisfaction.

- Cost Efficiency: Rapid prototyping reduces material costs and waste, decreasing the overall production budget. This efficiency benefits startups and large corporations alike.

- Speed: The speed of 3D printing allows for quicker turnaround times on prototypes and final products. Businesses gain a competitive advantage by reaching markets faster.

- Innovation: 3D techniques foster innovation by enabling complex designs that traditional manufacturing methods can’t achieve. This creativity drives industry advancement and diversification.

- Sustainability: Streamlined material use in additive manufacturing promotes sustainability. Many companies are adopting these techniques to minimize their environmental impact.

Challenges in 3D Production Techniques

3D production techniques face several challenges that can hinder their effectiveness. Two primary areas of concern include technical limitations and material constraints.

Technical Limitations

3D production techniques encounter technical limitations that impact workflow and output quality. These include software compatibility issues among various design programs, which can hinder collaboration among teams. Performance limitations of hardware, such as insufficient processing power or inadequate storage, can slow down rendering times and inhibit complex project execution. Resolution limits in 3D printing may also lead to less detailed outputs, affecting the overall quality of the final product. Optimizing software and hardware resources remains crucial for addressing these challenges and improving efficiency.

Material Constraints

Material constraints pose significant challenges in the realm of 3D production. Certain materials may lack the desired characteristics, such as durability or flexibility, affecting the usability of the final product. The availability of specialty materials, such as biocompatible plastics or specific alloys, can influence project timelines and costs. Moreover, compatibility of materials with different 3D printing technologies, including FDM and SLA, can restrict design options. Careful selection of materials based on project requirements ensures optimal results while navigating these constraints effectively.

Future of 3D Production Techniques

Rapid advancements in 3D production techniques are shaping the future of industries. Innovative technologies emerge consistently, enhancing efficiency and creativity. Industries increasingly adopt artificial intelligence (AI) for optimizing design processes, managing workflows, and predicting production outcomes. AI-driven software assists artists and engineers in creating complex models and refining prototypes quickly.

Emerging materials play a crucial role in 3D production. Biodegradable filaments and advanced composites enable sustainable practices, addressing environmental concerns. These materials enhance the quality and scope of 3D printed objects, catering to diverse applications from healthcare to consumer products.

Increased integration of virtual and augmented reality (AR) will redefine how professionals interact with 3D models. Collaborative platforms allow teams to visualize and manipulate designs in immersive environments. Enhanced collaboration enhances productivity and accelerates project timelines, meeting user demands effectively.

Customization continues to dominate the 3D production landscape. Consumers seek personalized products, driving businesses to innovate. On-demand manufacturing enables businesses to respond rapidly to market trends while minimizing waste and inventory costs.

Machine learning algorithms improve the performance of 3D printing processes. These algorithms optimize layer adhesion, speed, and material usage, thus ensuring high-quality output. The incorporation of machine learning leads to smarter, more efficient manufacturing environments.

Expect substantial advances in metal 3D printing technology. This sector is experiencing breakthroughs that make metal 3D printing more accessible and economically viable. Industries such as aerospace and automotive stand to benefit significantly from these innovations.

The convergence of 3D production techniques with other technologies enhances overall capabilities. Combining additive manufacturing with robotics streamlines operations, increasing precision and decreasing lead times. Such synergies redefine traditional workflows, showcasing the future’s innovative potential.

Continued exploration in bio-printing promises advances in tissue engineering and regenerative medicine. Researchers develop techniques to create functional biological tissues, revolutionizing healthcare and treatment methodologies.

As these innovations unfold, staying updated on trends and developments will be essential. Adapting to changing technologies will influence how artists, designers, and manufacturers approach their projects.

The evolution of 3D production techniques continues to reshape industries and redefine creative possibilities. As artists and professionals embrace these advancements they unlock new realms of innovation and efficiency. Staying abreast of the latest trends is essential for anyone looking to leverage the full potential of 3D technologies.

With the integration of AI and emerging materials the future promises even greater enhancements in design and production capabilities. The ongoing exploration of virtual and augmented reality will further transform interactions with 3D models. By navigating the challenges and harnessing the benefits of 3D production techniques professionals can ensure they remain at the forefront of their fields.