Table of Contents

ToggleAugmented reality and 3D printing are reshaping the way people interact with technology and design. These two groundbreaking innovations are merging to create immersive experiences that enhance creativity and efficiency. As industries explore the potential of combining virtual elements with tangible objects, the possibilities seem endless.

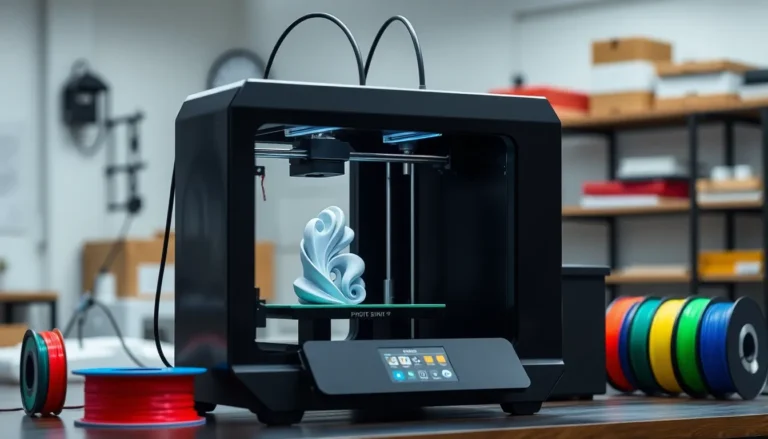

Imagine designing a product in a virtual space and then bringing it to life with a 3D printer. This synergy not only streamlines the design process but also allows for real-time modifications and visualizations. As businesses and individuals harness these technologies, they’re discovering new ways to innovate and solve complex problems, making the future of manufacturing and design more exciting than ever.

Overview of Augmented Reality and 3D Printing

Augmented reality (AR) overlays digital information onto the real world, enhancing user experiences. It uses devices like smartphones, tablets, and AR glasses to create interactive environments. Industries leverage AR to visualize products and interact with designs before physical production.

3D printing, or additive manufacturing, builds objects layer by layer from digital models. This technology enables the creation of complex shapes that traditional methods can’t achieve. 3D printers utilize materials like plastics, metals, and ceramics to produce functional prototypes, models, or end-use products.

The integration of AR and 3D printing enhances the design and prototyping phases. Users can design in AR, visualizing a product’s dimensions and functionality. Then they can transition seamlessly from the virtual prototype to production through 3D printing, facilitating rapid iterations.

Many industries benefit from this combination. Healthcare professionals use AR for surgical planning, while architects visualize building designs before construction. The automotive sector employs AR for design validation and 3D printing for producing custom parts efficiently.

This synergy between AR and 3D printing reduces production costs and time and enables tailored solutions. By merging these technologies, businesses are better equipped to innovate and solve complex problems, driving advancements across various sectors.

Applications in Various Industries

The integration of augmented reality (AR) and 3D printing drives significant advancements across multiple industries. These technologies enhance product development, streamline processes, and foster innovative solutions.

Healthcare Innovations

Healthcare leverages AR and 3D printing for improved patient care and surgical precision. Surgeons utilize AR for surgical overlays, allowing them to visualize critical anatomy during operations. 3D printing produces custom prosthetics and implants tailored to individual patient needs, drastically improving fit and function. A study from the Journal of Medical Internet Research indicated a 20% increase in surgical accuracy when AR was used for pre-operative planning.

Manufacturing Enhancements

Manufacturers adopt AR and 3D printing to optimize production lines and reduce waste. AR provides real-time data visualization during assembly, enabling workers to understand complex processes better. This decreases error rates and enhances efficiency. Additionally, 3D printing facilitates rapid prototyping, reducing the time from concept to production. According to a report by Deloitte, companies that implement these technologies can realize cost savings of up to 30%.

Educational Tools

Education incorporates AR and 3D printing to enhance learning experiences. AR provides interactive visualizations of complex subjects, allowing students to explore concepts in three dimensions. Meanwhile, 3D printing enables hands-on learning through the creation of physical models, facilitating deeper understanding. Research from the International Journal of Educational Technology states that students using these tools exhibit a 35% improvement in retention of information compared to traditional methods.

Benefits of Combining Augmented Reality and 3D Printing

The combination of augmented reality (AR) and 3D printing delivers significant advantages across various industries. By leveraging AR’s visualization capabilities alongside 3D printing’s manufacturing precision, organizations unlock new levels of creativity and efficiency.

Improved Design Visualization

Improved design visualization occurs as AR allows users to view digital models in real-world contexts. Designers and clients can interact with 3D representations, experiencing scale, color, and texture in an immersive manner. This experience reduces misunderstandings and aligns expectations before production starts. For instance, in architecture, stakeholders can walk through a virtual building, examining its layout and design features in detail. This iterative feedback process enhances collaboration and accelerates decision-making, minimizing costly design revisions.

Enhanced Prototyping Processes

Enhanced prototyping processes arise as AR and 3D printing streamline development workflows. Designers can visualize digital prototypes in AR, making adjustments based on real-time observations before producing physical models. This synergy allows for rapid iterations, reducing the time from concept to prototype significantly. For example, in the automotive sector, engineers can test and modify car components virtually, ensuring optimal performance before manufacturing. Combining AR with 3D printing also enables the creation of customized prototypes tailored to specific user needs, fostering innovation and improving product functionality across industries.

Challenges and Limitations

AR and 3D printing face several challenges and limitations that may hinder their widespread adoption and integration across industries.

Technical Barriers

Technical barriers significantly impact the adoption of AR and 3D printing. Compatibility issues arise when integrating software with various hardware systems, causing performance inconsistencies. Limited processing power in some devices restricts AR applications, resulting in lag and inaccurate overlays. Additionally, current 3D printing materials often lack the durability and variety needed for specific applications, necessitating ongoing research to enhance material properties and expand capabilities.

Costs and Accessibility

Costs associated with AR and 3D printing technologies present challenges for industries, especially small businesses. High initial investments in hardware and software can deter entry into the market. Furthermore, the costs for maintenance and updates increase over time, straining budgets. Accessibility also remains an issue, as regions lacking technological infrastructure may experience delays in adopting these innovations. These factors contribute to unequal opportunities, limiting the benefits of AR and 3D printing for various sectors.

Future Trends

Emerging trends in augmented reality (AR) and 3D printing indicate a promising future characterized by increased integration and functionality. Enhanced user experiences drive the development of AR applications, creating more intuitive interfaces. Advanced AR tools will likely enable users to manipulate 3D models in real-time, improving visualization and design interaction across various industries.

Expanding applications in healthcare represent a significant trend. Surgeons increasingly utilize AR for real-time anatomical visualization during procedures. The 3D printing of biocompatible materials enables the production of custom implants and prosthetics tailored to individual patient needs, illustrating the convergence of these technologies.

Automation and artificial intelligence (AI) integration into 3D printing workflows enhance design and production processes. Smart algorithms will streamline design iterations, optimize material usage, and reduce waste. Combined with AR’s visualization capabilities, these technologies promote more sustainable practices in manufacturing.

Collaboration between industries continues to evolve. Virtual and augmented environments allow teams to work together on designs, regardless of geographic location. This collaborative approach increases innovation and accelerates product development, positioning businesses to compete effectively in the market.

Education will also experience significant transformations. Incorporating AR and 3D printing into curriculums enriches STEM education, offering students immersive learning experiences. Schools that adopt this technology foster higher engagement and knowledge retention compared to traditional learning methods.

Challenges remain, such as addressing technical limitations and cost barriers. Continuous advancements in hardware and software aim to mitigate issues like processing power and compatibility. Tracking the evolution of these industries is crucial, as solutions developed today lay the groundwork for tomorrow’s innovations.

The fusion of augmented reality and 3D printing is reshaping how industries approach design and production. This powerful combination enhances creativity and streamlines processes, leading to more efficient workflows and tailored solutions. As these technologies continue to evolve, they promise to unlock even greater potential across various sectors.

Future advancements will likely focus on improving user experiences and expanding capabilities. By addressing existing challenges and fostering collaboration, AR and 3D printing will pave the way for innovative solutions that drive growth and efficiency. Embracing these technologies will be essential for staying competitive in an ever-changing landscape.