Table of Contents

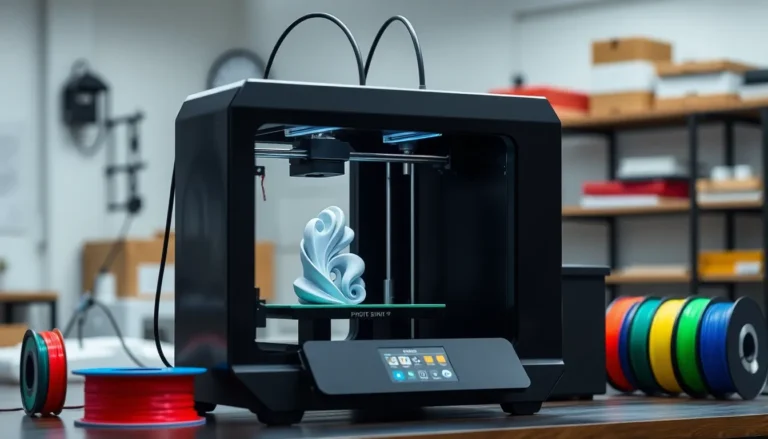

ToggleIn a world where everything seems to be getting faster and more complex, additive manufacturing—better known as 3D printing—stands out as the superhero of production. It’s like having a magic wand that turns digital designs into tangible objects faster than you can say “print me a coffee mug.” From creating intricate prototypes to producing custom parts, this technology is revolutionizing industries and making dreams a reality, one layer at a time.

Overview of Additive Manufacturing 3D Printing

Additive manufacturing, commonly known as 3D printing, encompasses various technologies that create three-dimensional objects layer by layer from digital models. This innovative process utilizes materials such as plastics, metals, and ceramics, allowing for immense flexibility in product design. Manufacturers can produce lightweight, complex shapes that traditional methods struggle to replicate.

Popular techniques in additive manufacturing include Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). FDM operates by extruding melted filament through a nozzle, while SLA employs a UV light source to solidify liquid resin. SLS uses powdered materials, fusing them with a laser to form durable parts.

Industries leveraging additive manufacturing span aerospace, automotive, healthcare, and consumer goods. In aerospace, companies reduce weight and enhance fuel efficiency with optimized components. The automotive sector benefits from rapid prototyping, which accelerates the design process. Healthcare professionals utilize 3D printing for custom implants and surgical tools, improving patient outcomes.

Cost savings often accompany the adoption of additive manufacturing. Reducing material waste and minimizing production time contributes to overall efficiency. Customization becomes feasible without the need for extensive retooling, opening new avenues for personalized solutions.

Adoption rates for additive manufacturing continue to rise, with projections indicating significant growth in the coming years. Businesses increasingly recognize 3D printing as a viable method for both small-scale and mass production. Enhanced capabilities in software and material science further bolster its application potential, promising continued innovation in various sectors.

Types of Additive Manufacturing Technologies

Additive manufacturing encompasses several technologies that cater to different needs and applications in various industries. Below are three prominent methods used in 3D printing.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling represents one of the most commonly utilized additive manufacturing techniques. This process involves extruding thermoplastic filaments through a heated nozzle, building objects layer by layer. Materials like PLA and ABS are often used due to their availability and affordability. FDM is prominent in prototyping and small-scale production, appealing to hobbyists and professionals alike. The simplicity of the technology allows for easy setup and operation, making it accessible for newcomers to 3D printing.

Stereolithography (SLA)

Stereolithography is known for producing highly detailed and accurate parts. Using a laser to cure liquid resin, this method creates layers to form objects with intricate geometries. Resin types vary, allowing users to select properties suited for specific applications, such as flexibility or rigidity. High-resolution prints from SLA are often used in industries like jewelry and dental for precise models. The post-processing required for SLA, which includes cleaning and curing, enhances the final appearance and durability of printed items.

Selective Laser Sintering (SLS)

Selective Laser Sintering offers significant advantages in terms of material choices and production efficiency. This technology utilizes a laser to fuse powdered materials, typically nylon and metal, into solid structures. SLS supports complex geometries, leading to minimal support structures and waste. It’s widely adopted in aerospace and automotive applications, where strength and lightweight components are crucial. The versatility in material selection, along with its suitability for both prototyping and production runs, makes SLS a powerful additive manufacturing option.

Applications of Additive Manufacturing 3D Printing

Additive manufacturing extends its influence across various industries, revolutionizing how products are designed and produced.

Aerospace Industry

In aerospace, companies leverage 3D printing for lightweight components that enhance fuel economy. Parts like brackets, ducts, and even engine components benefit from this technology due to customized geometries, achieving reduced weight without sacrificing strength. Boeing, for instance, uses additive manufacturing to develop complex designs while minimizing material waste. The industry sees substantial cost savings from shortened production times, with rapid prototyping enabling faster testing and iteration.

Medical Field

The medical field embraces additive manufacturing for creating personalized implants and prosthetics tailored to individual patients. Surgeons employ 3D-printed models to plan complex procedures, enhancing surgical precision. Companies like Materialise produce patient-specific surgical guides that improve implant placement accuracy. Additionally, bioprinting is emerging, offering possibilities for printing tissues and organs, which could revolutionize transplant procedures. This sector’s focus on customization leads to improved patient outcomes.

Consumer Products

In consumer products, 3D printing supports rapid prototyping and personalized merchandise. Companies can design and manufacture unique items that cater to specific customer preferences, driving engagement and satisfaction. For example, brands like Nike utilize additive manufacturing for creating custom footwear, allowing for personalized fit and style. Moreover, product iterations can be achieved more rapidly, reducing time to market and enabling companies to adapt quickly to consumer trends. The flexibility of this technology fosters innovation across the consumer goods landscape.

Advantages and Challenges

Additive manufacturing brings both compelling advantages and notable challenges to modern production processes. Understanding these aspects is vital for businesses considering this innovative technology.

Benefits of Additive Manufacturing

Cost efficiency stands out as a significant advantage. Additive manufacturing minimizes material waste by using only the necessary amount of material for each layer. Speed also plays a critical role; producing complex parts takes hours rather than weeks and enables businesses to meet tight deadlines. Customization offers another key benefit, allowing for personalized designs tailored to specific consumer needs. Flexibility in design further enhances this technology, permitting intricate geometries that traditional manufacturing can’t achieve. Diverse applications span industries, making additive manufacturing widely applicable from aerospace to healthcare.

Limitations and Considerations

Despite the advantages, challenges accompany additive manufacturing. Material limitations exist; not all materials are suitable for every application, which can restrict options. Equipment costs can also be high, often posing a barrier for small businesses. Speed, while generally beneficial, may not match large-scale production rates seen in traditional methods. Layer adhesion can impact the strength of parts, necessitating careful consideration during design. Regulatory hurdles may arise, especially in industries like aerospace and healthcare, where compliance with standards is crucial. Understanding these limitations ensures better implementation strategies and outcomes in additive manufacturing.

Future Trends in Additive Manufacturing 3D Printing

Innovation in additive manufacturing continues to evolve, focusing on enhancing production capabilities. Increased use of materials such as bio-based plastics emphasizes sustainability. Emerging trends include the integration of artificial intelligence, which streamlines design processes and optimizes printing operations. Companies explore greater customization opportunities, allowing for unique product designs that cater to specific consumer needs.

A notable aspect under development is the expansion of metal 3D printing, making it suitable for high-performance applications. Industries like aerospace, where lightweight and durable components are essential, benefit significantly from this advancement. Furthermore, the healthcare sector increasingly adopts bioprinting for fabricating human tissues, contributing to personalized medicine.

Collaborative robots, or cobots, gain traction in additive manufacturing settings, enhancing efficiency and safety. These robots assist human operators, enabling higher productivity levels while maintaining precision. Additionally, advancements in software tools expedite the design phase, increasing the speed of product development and allowing for real-time modifications.

Integration of IoT technology continues to reshape additive manufacturing. This connectivity allows equipment to communicate, monitor performance metrics, and predict maintenance needs, minimizing downtime. Advanced post-processing techniques are also emerging, focusing on improving surface finishes and meeting industry standards.

As businesses prioritize sustainability, recycling of 3D printed materials becomes more prevalent, promoting a circular economy. Organizations actively seek ways to repurpose waste materials generated during the printing process. Finally, ongoing advancements in education and training programs equip the workforce with essential skills, preparing them for future challenges in additive manufacturing.

Additive manufacturing is reshaping the landscape of production across multiple industries. Its ability to quickly transform digital designs into tangible products offers unmatched flexibility and efficiency. As companies continue to harness its potential for customization and rapid prototyping, the future looks bright for this innovative technology.

With advancements in materials and processes, additive manufacturing is set to overcome existing challenges and drive sustainable practices. The integration of AI and IoT will further enhance production capabilities, making it a cornerstone of modern manufacturing. Embracing these trends will enable businesses to stay competitive and meet the evolving demands of their markets.