Table of Contents

ToggleIn a world where the quest for lighter, stronger materials feels like a superhero saga, carbon fiber 3D printing swoops in to save the day. Imagine crafting complex designs that not only look sleek but also boast the strength of a bodybuilder on a protein shake binge. This cutting-edge technology isn’t just for rocket scientists anymore; it’s making waves in industries from aerospace to automotive, and even your favorite hobbyist’s workshop.

Overview of Carbon Fiber 3D Printing

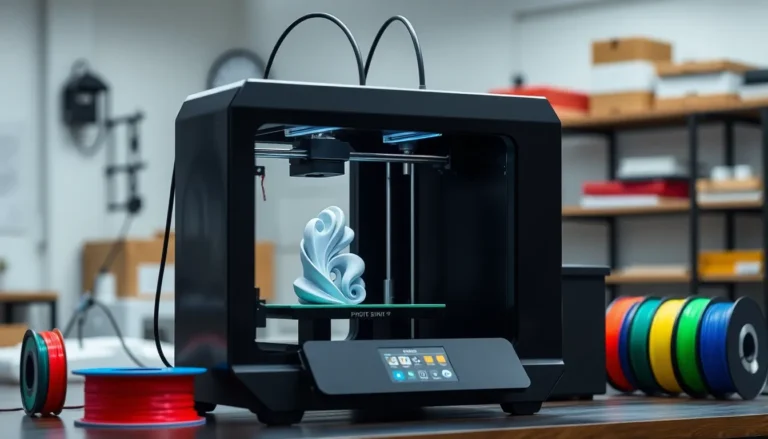

Carbon fiber 3D printing represents a significant advancement in additive manufacturing technology, combining strength with lightweight properties. This method utilizes carbon fiber filaments, which enhance the mechanical characteristics of 3D printed parts. Industries like aerospace and automotive benefit from the ability to produce parts that endure high stress while remaining cost-effective.

The printing process often involves composite materials, which incorporate carbon fiber into various thermoplastics. These composites yield strong, durable components capable of withstanding extreme temperatures and pressures. Elevated performance attributes make carbon fiber 3D printing suitable for functional prototypes and end-use parts.

Precision plays a crucial role in achieving desired mechanical properties. High-quality printers use advanced extrusion techniques and temperature control, ensuring optimal bonding strength between layers. Additionally, specific geometries can be achieved that traditional manufacturing methods struggle to replicate.

Applications span numerous sectors, from custom automotive components to lightweight drone frames. As accessibility improves, hobbyists embrace this technology for projects ranging from model making to small aerospace prototypes. Carbon fiber 3D printing stands poised to influence future manufacturing approaches significantly.

Cost considerations impact its adoption. While initial investments may seem high, long-term durability and reduced production times offer substantial savings. Businesses should assess these factors when evaluating integration into existing workflows. This technology continues to evolve, allowing for improved materials and techniques that enhance functionality and versatility across diverse applications.

Benefits of Carbon Fiber 3D Printing

Carbon fiber 3D printing offers numerous advantages that make it a preferred choice for various applications. Key benefits include enhanced strength and durability as well as impressive lightweight properties.

Strength and Durability

Strength and durability rank among the primary benefits of carbon fiber 3D printing. Carbon fiber filaments provide exceptional tensile strength, making parts resistant to fractures and deformations. High-performance applications often require materials that can withstand significant stress. Carbon fiber components excel in these scenarios, showing remarkable stability under various conditions. They endure extreme temperatures and resist corrosive substances, making them suitable for aerospace and automotive applications. This durability translates into reduced maintenance costs over time, ensuring a longer lifespan for produced parts.

Lightweight Properties

Lightweight properties significantly enhance the appeal of carbon fiber 3D printing. Reduced weight in components enables higher efficiency in applications like drones and vehicles. Carbon fiber’s unique composition offers strength without the bulk typically associated with metals and other materials. Lower weight directly affects fuel consumption and performance, leading to improved operational efficiency. This advantage allows for faster production times and easier handling during assembly. Professionals and hobbyists alike can benefit from the overall improvement in project feasibility due to these lightweight characteristics.

Applications of Carbon Fiber 3D Printing

Carbon fiber 3D printing finds diverse applications across multiple industries, showcasing its versatility and strength.

Aerospace Industry

In aerospace, carbon fiber 3D printing plays a vital role in producing lightweight components for aircraft. The ability to create complex geometries reduces weight without sacrificing structural integrity. From brackets to ducts, carbon fiber parts enhance fuel efficiency and performance. Manufacturers utilize this technology to streamline production processes, decreasing lead times significantly. High-strength materials meet rigorous safety standards, making them ideal for critical applications in flight. Specific examples include custom tooling and interior structures that contribute to overall weight reduction.

Automotive Industry

The automotive industry leverages carbon fiber 3D printing to create robust yet lightweight parts that improve vehicle performance. Car manufacturers design components such as chassis, spoilers, and interior features using this technology. Enhanced mechanical properties result in improved fuel efficiency and reduced emissions. Customization leads to unique designs, allowing brands to differentiate themselves in a competitive market. Advanced printing techniques also enable rapid prototyping, reducing time to market for new models. Carbon fiber’s resistance to wear and fatigue ensures durability under demanding driving conditions.

Consumer Products

Consumer products benefit greatly from carbon fiber 3D printing, offering lightweight and durable options for a variety of applications. Products like custom electronics housings, sporting goods, and fashion accessories utilize this material for enhanced aesthetics and performance. The lightweight nature provides users with ease of handling and improved usability. Unique designs become feasible, catering to niche markets and individual preferences. Manufacturing becomes cost-effective as production scales up, allowing for high-quality, innovative products at competitive prices. Carbon fiber’s unique appearance also attracts consumers seeking premium features.

Challenges in Carbon Fiber 3D Printing

Carbon fiber 3D printing presents distinct challenges, particularly regarding material and printability.

Material Limitations

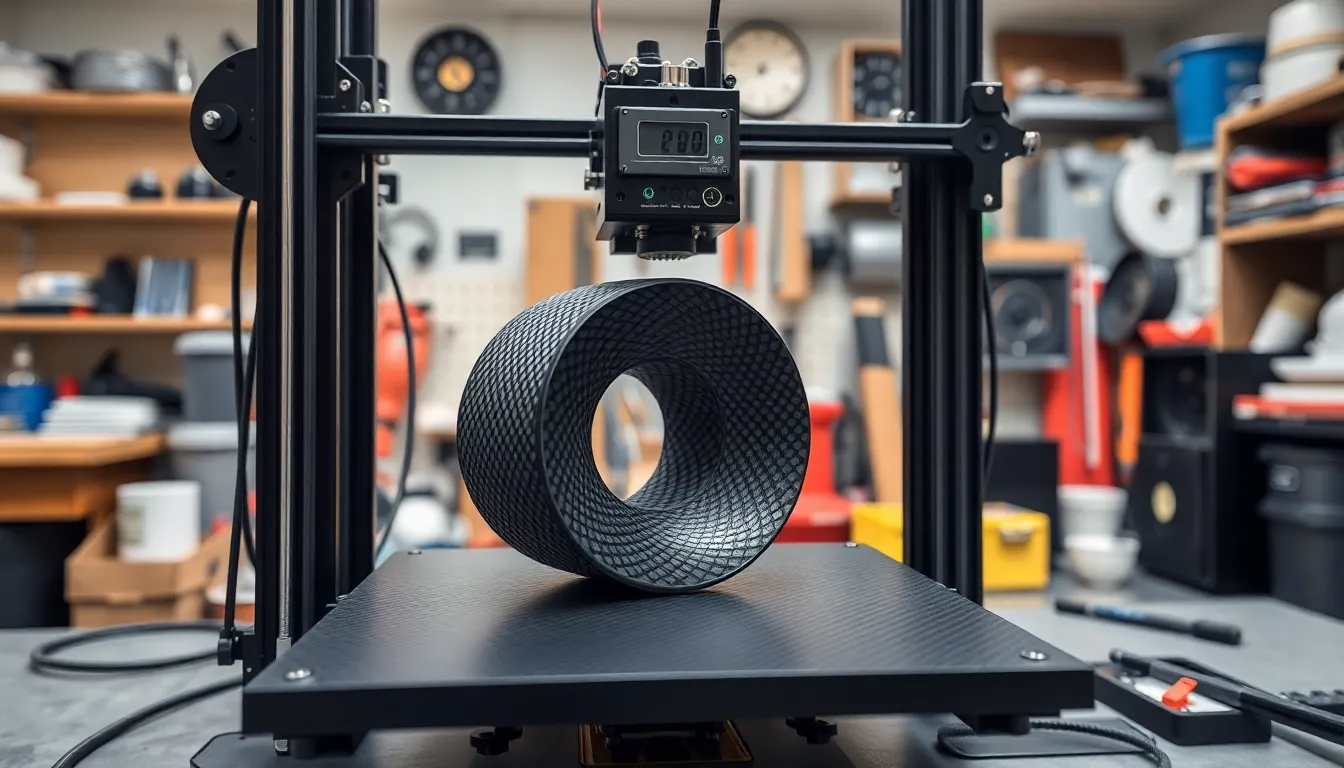

Material options remain restricted when utilizing carbon fiber filaments. Certain filaments may lack compatibility with various 3D printers, limiting their application. Many carbon fiber composites require specific conditions to ensure optimal performance, which can complicate the manufacturing process. The presence of fibers can lead to increased wear on printer nozzles, necessitating more frequent replacements. Furthermore, achieving the desired mechanical properties often depends on the combination of base materials, presenting additional challenges for designers. The strength-to-weight ratio benefits are significant, yet diverse material sources are crucial for effective implementation.

Printability Issues

Printability concerns arise when working with carbon fiber composites. Difficulty can occur during the extrusion process, as filament consistency plays a critical role in quality. Variability in filament diameter may lead to inconsistent flow and layer adhesion issues. Moreover, it’s essential to maintain appropriate printing temperatures; too high may degrade the material while too low affects bonding strength. Layering techniques also impact the final product’s structural integrity. Commonly, achieving precision in complex geometries presents unique challenges in carbon fiber 3D printing.

Future Trends in Carbon Fiber 3D Printing

Emerging innovations in carbon fiber 3D printing promise to reshape various industries. Enhanced material formulations are likely to improve printability and expand the range of compatible 3D printers. As technology advances, hybrid printing methods may combine layered techniques with traditional manufacturing, allowing for intricate designs that maintain strength.

Growing interest in sustainability drives further development. Bio-based carbon fiber alternatives will likely emerge, minimizing environmental impact while retaining desirable properties. This shift caters to eco-conscious consumers and aligns with global sustainability goals.

Integration of artificial intelligence in the design process stands to revolutionize carbon fiber applications. AI can analyze and optimize designs for specific performance parameters, leading to more efficient and effective parts. This trend enhances the customization of components for diverse use cases.

Collaboration between various sectors fuels innovation. Aerospace and automotive industries are likely to continue leading the way in carbon fiber adoption, paving the way for improved designs in consumer products. As companies share knowledge and resources, the rate of advancement in carbon fiber 3D printing technology will increase.

The focus on automation and smart manufacturing will transform production capabilities. Fully automated systems could streamline workflows and reduce human error, further enhancing part quality. Increased efficiency in production processes can lead to significant cost savings and faster delivery times.

Future trends reveal a promising landscape for carbon fiber 3D printing, driven by developments in materials, automation, and AI integration. Companies experts and enthusiasts alike can expect increased accessibility to this advanced technology. Carbon fiber’s lightweight yet robust characteristics will continue to benefit various engineering applications, ensuring its place in future manufacturing strategies.

Carbon fiber 3D printing is redefining manufacturing capabilities across multiple sectors. Its unique combination of strength and lightweight properties positions it as a game-changer for industries like aerospace and automotive. As accessibility improves and innovations emerge, this technology is set to lead the way in creating efficient and durable components.

While challenges remain, the ongoing advancements in material formulations and design processes promise to enhance the printability and performance of carbon fiber applications. The focus on sustainability and automation is likely to further drive its adoption. Embracing these developments will enable professionals and hobbyists alike to leverage the full potential of carbon fiber 3D printing, shaping the future of additive manufacturing.