Table of Contents

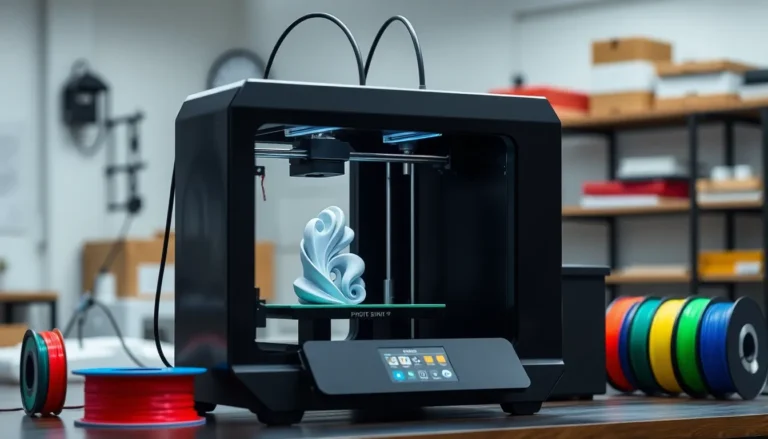

ToggleIn a world where creativity knows no bounds, EOS 3D printing stands at the forefront, transforming dreams into reality—one layer at a time. Imagine crafting anything from intricate prototypes to custom parts, all while sipping your morning coffee. Sounds like magic, right? Well, it’s just the power of additive manufacturing at work.

EOS 3D printing isn’t just for tech wizards in lab coats; it’s for anyone with a vision. Whether you’re an entrepreneur looking to revolutionize your industry or a hobbyist eager to impress your friends, this technology offers endless possibilities. So buckle up and get ready to explore how EOS is reshaping the way we design, create, and innovate. Who knew the future could be so much fun?

Overview of EOS 3D Printing

EOS 3D printing revolutionizes the field of additive manufacturing. It creates complex structures layer by layer, utilizing high-performance materials like metals and polymers. This technology supports various industries, including aerospace, automotive, and medical sectors.

EOS printers deliver precision and accuracy in creating parts, ensuring consistency and reliability. Companies use this process to develop prototypes rapidly, reducing time to market. Users customize designs easily, meeting specific project requirements.

The versatility of EOS 3D printing allows for the production of both small and large components. Its laser sintering technology is notable for advancing the creation of durable end-use parts. Manufacturers can also optimize their production workflows, enhancing efficiency significantly.

A range of materials is available for EOS 3D printing. Users can select from polymers such as PA 12, metals like titanium, and even specialty materials. Each material offers unique properties, catering to diverse applications.

Through the use of smart software, EOS streamlines the entire manufacturing process. This integration improves workflow management, allowing for real-time monitoring and control. Consequently, companies can enhance productivity while maintaining high standards of quality.

Overall, EOS 3D printing opens new avenues for innovation. Its ability to transform ideas into functional products benefits entrepreneurs and manufacturers alike. The technology encourages exploration and experimentation, empowering users to push creative boundaries.

Technology Behind EOS 3D Printing

EOS 3D printing utilizes advanced additive manufacturing technologies to produce high-quality components from various materials. This section details key aspects of its innovative processes.

Powder Bed Fusion Process

The powder bed fusion process forms the backbone of EOS 3D printing. It involves layering fine powdered material, which is selectively melted using a laser. Each layer builds on the previous one, creating complex geometries with precision and detail. This method excels in producing intricate designs, ranging from prototypes to end-use parts. Materials like PA 12 and metal powders get employed, catering to diverse application needs. The ability to create lightweight yet durable structures provides significant advantages in sectors like aerospace and automotive. Fast production speeds paired with high accuracy make powder bed fusion an essential component of modern manufacturing.

Laser Sintering Techniques

Laser sintering techniques lie at the heart of EOS 3D printing innovation. A focused laser beam fuses powdered material by heating it to just below its melting point. This selective process allows for exceptional control over material properties, enhancing the final product’s strength and versatility. Various materials, including thermoplastics and metals, lend themselves well to laser sintering, enabling manufacturers to tailor components for specific functions. The technology’s efficiency in producing complex parts with minimal waste contributes to more sustainable practices in manufacturing. As a result, laser sintering positions itself as a frontrunner in additive manufacturing, driving advancements in design and engineering solutions.

Applications of EOS 3D Printing

EOS 3D printing finds extensive applications across various industries, showcasing its versatility and efficiency in producing high-quality parts.

Aerospace Industry

The aerospace industry utilizes EOS 3D printing for producing lightweight components. Manufacturers benefit from the ability to design intricate parts that enhance fuel efficiency. Notably, titanium and aluminum materials are prevalent in aircraft parts due to their strength-to-weight ratio. End-use components like brackets and fuselage parts can often be created using additive manufacturing processes, significantly reducing lead times. Companies in aerospace appreciate rapid prototyping, which shortens development cycles and enables testing of innovative designs.

Medical Sector

In the medical sector, EOS 3D printing revolutionizes patient care with tailored solutions. Custom implants and prosthetics manufactured using this technology enhance comfort and functionality. Biocompatible materials allow for safe applications in surgical procedures, spurring advancements in regenerative medicine. Medical professionals favor the precision EOS technology provides, allowing for complex geometries to be created and optimized for individual patients. Additionally, rapid prototyping plays a role in developing medical devices, ensuring efficiency in production and allowing for swift adjustments during the design phase.

Automotive Innovations

The automotive industry leverages EOS 3D printing to enhance production efficiency and design capabilities. This technology allows for rapid prototyping of parts like engine components and interior fixtures. Companies benefit from reduced material waste, as the additive nature of the process minimizes excess. Engineers can create specialized tools and fixtures that improve assembly line processes, streamlining operations. With a focus on lightweight materials, vehicles become more fuel-efficient and sustainable. EOS 3D printing supports innovative designs that push the boundaries of traditional manufacturing, enabling automotive manufacturers to stay competitive in the market.

Advantages of EOS 3D Printing

EOS 3D printing offers significant advantages in modern manufacturing, specifically in precision, quality, and material versatility. Users find it enables the creation of complex parts with unmatched detail.

Precision and Quality

Precision defines the EOS 3D printing process. Layer-by-layer construction allows for intricate designs, ensuring tight tolerances. Users report consistent quality throughout production runs, with minimal defects and variations. Advanced laser technology fosters reliable melting of powdered materials, resulting in strong bonds between layers. Such meticulous attention to detail meets the stringent demands of industries like aerospace and medical. Businesses benefit from high-quality end products that stand the test of time.

Material Versatility

Material versatility stands as a hallmark of EOS 3D printing. A wide array of materials, including specialized polymers and metals, caters to various needs. Engineers utilize materials like PA 12 for lightweight yet durable parts and titanium for robust applications. Diverse properties within these materials allow for fine-tuning based on specifications. Users appreciate how easily they can adapt designs to specific requirements, enhancing customization capabilities. This extensive material selection empowers industries to pursue innovative solutions and optimize performance across different applications.

Challenges and Limitations

EOS 3D printing presents several challenges and limitations that users must navigate.

Cost Factors

Cost remains a significant consideration in EOS 3D printing. Initial equipment investment can range from tens of thousands to millions of dollars, depending on the machine model. Material costs also accumulate, as specialized powders for metal or polymers possess higher prices than conventional materials. Maintenance expenses arise from the need for regular servicing and calibration to maintain optimal performance. Moreover, energy consumption during production can lead to increased operational costs, influencing profitability. Businesses must weigh these financial factors against the potential for innovation and increased workflow efficiency.

Technical Complexities

Technical complexities complicate the adoption of EOS 3D printing. Expertise in operating the machines is essential, as improper setup or settings can result in defects or failed prints. Understanding the intricacies of different materials is crucial, as each requires unique handling and processing techniques. Software integration can also pose challenges, especially if systems do not communicate seamlessly. Additionally, troubleshooting various issues, such as powder quality or laser calibration, necessitates skilled personnel. Companies may find it essential to invest in training and support to fully leverage the technology’s capabilities.

EOS 3D printing stands at the forefront of modern manufacturing, offering remarkable opportunities for innovation across various industries. Its ability to create intricate designs with precision and speed positions it as a game-changer for entrepreneurs and established companies alike. The technology not only enhances efficiency but also encourages creativity, allowing users to explore new possibilities in product development.

While challenges like cost and technical expertise exist, the potential benefits far outweigh these hurdles. As industries continue to embrace EOS 3D printing, the future looks promising for those willing to adapt and innovate. Embracing this technology could lead to significant advancements in design and production, paving the way for a new era of manufacturing excellence.