Table of Contents

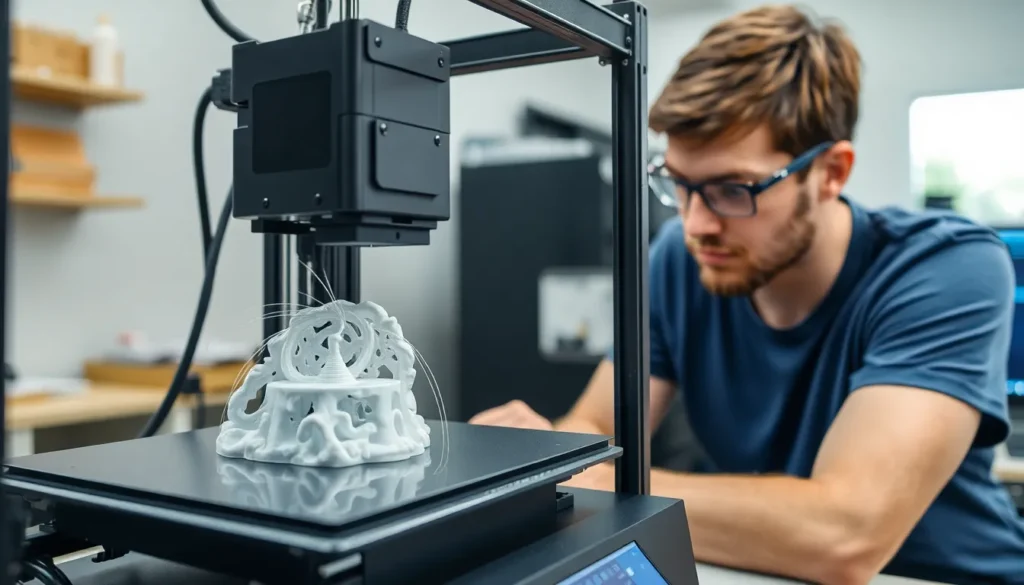

Toggle3D printing is a magical world where imagination meets reality, but it’s not all rainbows and unicorns. Enter stringing—the pesky little issue that can turn a beautiful print into a spaghetti nightmare. Picture this: you’ve designed the perfect model, only to find it adorned with unwanted strands that resemble a bad hair day. Frustrating, right?

Overview of Stringing in 3D Printing

Stringing poses a challenge in 3D printing, often leading to unsightly threads on printed models. This phenomenon occurs during the printing process, detracting from the final product’s overall quality.

What Is Stringing?

Stringing refers to the formation of thin strands of filament between parts of a model when the printer’s nozzle moves. Filament can ooze out due to pressure and heat during non-print movements. This issue commonly appears on hollow or intricate designs. When the extruder nozzle travels from one point to another, it may leak material, creating unsightly artifacts. Models intended for functionality or aesthetics require stringing mitigation for optimal results.

Causes of Stringing

Several factors contribute to stringing during 3D printing. Temperature settings play a crucial role; higher nozzle temperatures often increase filament flow, leading to more stringing. Additionally, travel speed significantly impacts stringing; slower movements can result in excessive filament melting and oozing. Retraction settings also matter; inadequate retraction can fail to pull filament back, allowing it to leak. Filament type influences stringing occurrence as well; some materials tend to string more easily than others. Finally, environmental conditions such as humidity can affect filament properties, worsening the stringing issue.

Effects of Stringing on Prints

Stringing negatively impacts the overall quality of 3D prints. These consequences manifest visually and functionally, affecting both aesthetics and usability.

Visual Impacts

Stringing leads to visible strands of filament on prints. These unwanted threads create a messy appearance, disrupting clean lines and intricate details. Such imperfections can make a model look unprofessional and diminish its visual appeal. High-resolution prints become a challenge when stringing occurs. Models meant for display lose their intended impact due to unappealing artifacts. Even light exposure can accentuate these flaws, further detracting from the aesthetic value of the print.

Functional Impacts

Stringing can compromise a print’s functionality. Excess filament can interfere with moving parts, resulting in mechanical failures or restricted movement. Tight fits might not operate as intended, affecting overall performance. In technical applications, precision is crucial; even minor errors from stringing can lead to significant issues. Furthermore, additional post-processing may be necessary to remove strands, extending project time and costs. Such inefficiencies warrant careful consideration during the printing process.

Techniques to Reduce Stringing

Stringing can significantly affect print quality, but several techniques can help mitigate this issue.

Optimizing Print Settings

Adjusting print settings provides a direct approach to reducing stringing. Lowering the nozzle temperature can prevent filament from becoming too fluid, minimizing the likelihood of strands. Increasing travel speed helps by limiting the amount of time the nozzle spends moving between print areas, which can reduce oozing. Additionally, implementing retraction settings can effectively pull filament back into the nozzle during travel, preventing drips. Fine-tuning these settings based on specific filament types often leads to noticeable improvements in print quality.

Using the Right Materials

Choosing the correct filament plays a crucial role in reducing stringing. For instance, PLA tends to string less than other materials, making it a suitable choice for detailed prints. Some brands of PETG and ABS include additives designed to decrease stringing. Exploring specialty filaments that minimize oozing may also yield beneficial results. Recognizing the relationship between filament characteristics and printing outcomes allows for more informed material selections, ultimately leading to better print quality.

Troubleshooting Stringing Issues

Stringing issues often impede 3D printing quality. Identifying common problems and applying solutions plays a key role in achieving better results.

Common Problems and Solutions

Extruder temperature may be set too high, causing filament to ooze during movement. Lowering the temperature in increments of 5°C can lead to significant improvements. Travel speed also affects stringing; increasing this variable reduces the time the nozzle spends in motion, which minimizes filament leakage. Adjusting retraction length, typically around 1-6 mm, enhances filament pull-back between prints. Humidity plays a part too; storing filament in a dry environment protects it from moisture that can worsen stringing. Lastly, evaluating the type of filament helps. Choosing brands known for reduced stringing can lead to smoother prints.

When to Seek Professional Help

Persistent stringing issues may indicate deeper mechanical concerns. If adjustments yield no results, inspecting key components like the nozzle and hotend is crucial. Cleaning or replacing a clogged nozzle can restore optimal flow and minimize filament leaks. Printer calibration is another aspect to consider; misaligned axes or poor bed adhesion causes additional complications. Persistent issues also warrant reviewing firmware settings. If users lack confidence in performing these fixes, consulting with a 3D printing specialist ensures proper assessment and guidance. This support can save both time and materials, ensuring prints meet expected quality standards.

Stringing in 3D printing is a challenge that can significantly impact the quality of prints. By understanding its causes and implementing effective strategies, users can achieve cleaner and more precise results. Optimizing print settings and selecting the right materials are crucial steps in minimizing stringing.

Regular maintenance of the printer and proper filament storage further enhance print quality. For those struggling with persistent stringing issues, seeking expert advice can lead to improved outcomes. Embracing these techniques not only saves time and resources but also elevates the overall 3D printing experience, allowing for greater creativity and innovation in projects.